Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Aluminum and its alloys are widely used in various industries due to their excellent strength-to-weight ratio and good corrosion resistance. However, applying a high-quality, durable PVD (Physical Vapor Deposition) coating directly onto an untreated aluminum surface is challenging. To ensure optimal adhesion, appearance, and performance, a series of precise pre-treatment steps are absolutely crucial before the components are loaded into the Coating Equipment.

Critical Pre-Treatment Steps for Aluminum:

Degreasing and Cleaning: Any residual oils, greases, or contaminants from machining and handling must be completely removed. This is typically done using ultrasonic cleaning or alkaline cleaning solutions to ensure a perfectly clean surface.

Polishing and Grinding: The surface finish of the aluminum substrate directly affects the final appearance of the PVD coating. Processes like mechanical polishing or buffing are employed to achieve the desired smoothness, mirror finish, or specific texture, which eliminates minor surface imperfections.

Precision Drying: After cleaning and any wet processes, the parts must be thoroughly and completely dried. Any moisture trapped on the surface will vaporize in the vacuum chamber, causing defects and adhesion failure in the coating.

For certain aluminum alloys or applications requiring extreme durability, an additional step is often incorporated:

Electroplating or Anodizing: A layer of electrodes nickel (EN plating) is a common pre-coat. It creates a hard, uniform barrier that prevents the aluminum from oxidizing and provides an excellent, consistent surface for PVD adhesion. In some cases, a thin, sealed anodic layer may also serve as a substrate. This step is vital for preventing the aluminum substrate from outgassing and for achieving a flawless finish with advanced coating equipment like the PVD Multiarc Ion Sputtering Coating Machine.

PVD Coating on Aluminum with Advanced Equipment

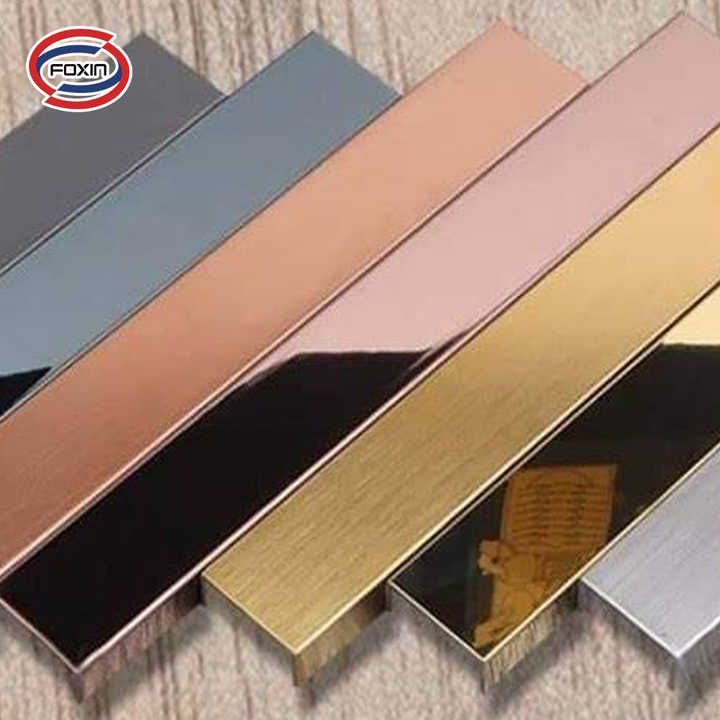

Once pre-treated, aluminum components are ready for the PVD process. This involves placing them inside a high-vacuum chamber where a coating material is vaporized and deposited onto the surface, forming a thin, ultra-hard, and wear-resistant layer. This process significantly enhances the product's properties, providing superior corrosion resistance and an attractive, durable decorative coating.

Key technologies for this stage include the GD Large Multiarc Ion Sputtering Machine, ideal for processing large batches or big components with high efficiency, and the TG Multiarc Ion Sputtering Machine, known for its stability and precision in creating uniform coatings on complex geometries. The use of such sophisticated Coating Equipment ensures the final product achieves excellent adhesion promotion, vibrant colors, and enhanced surface hardness, making PVD-coated aluminum ideal for automotive trim, consumer electronics, luxury accessories, and architectural hardware.

Conclusion

In summary, achieving a successful and high-quality PVD finish on aluminum products is a two-stage commitment. It begins with meticulous and non-negotiable pre-treatment—including thorough cleaning, polishing, and often an intermediate layer like electrodes nickel—to prepare the substrate. This foundational work is then elevated by advanced PVD technology, such as Multiarc Ion Sputtering systems, which apply the final functional and decorative coating. The synergy between perfect surface preparation and state-of-the-art coating processes is what unlocks the full potential of PVD on aluminum, resulting in products that are not only visually stunning but also exceptionally durable and resistant to wear and corrosion.

Let's get in touch.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.